corporate

Aluminium Technology and Auxiliary Industries WLL or Alutec in short, is Qatar’s largest aluminium and glazing company, specializing in architectural aluminium and glass products, aluminium doors, windows, skylights, cladding projects and unitized and standard curtain walls.

Started in 1995 by Thampi Narayanan, in partnership with the HBK Group headed by Sheikh Ali Bin Hamad Bin Khalifa Al Thani, Alutec has grown to be one of the most reputed organizations in the Middle East North Africa (MENA) region. Alutec has established itself as one of the pioneers and a market leader in the aluminium and glass industry, in a very short span of time since its inception. The company stands apart with its novel design solutions, unmatched technical supremacy and the biggest production facilities in the region.

Our capacity to provide true end-to-end solutions and commitment to meet the increasingly diverse needs of our customers through technological innovation, state-of-the-art-design, quality control, global supply chain management, and consistent investments in production and processing facilities is what differentiates Alutec from our competitors.

our values

_____

Our core values at Alutec are professionalism, integrity, reliability, quality and service excellence, while our ongoing mission is to deliver exceptional value to our customers in the MENA region while expanding our footprint internationally, by providing superior quality architectural Aluminium, glass and metal products and systems, supported by our unrivaled service.

To achieve our core values and mission, Alutec is focused on continuous improvements by expanding on our area of expertise, portfolio of products, production capacity, supply chain and staying at the forefront of technological and industry innovations, while growing and nurturing our team of experts who resonate with the company mission and values.

material management

_____

Alutec’s Materials management department manages the supply chain of the organization and the materials used for processing, production, manufacturing and installation of our products.

Alutec uses a customized Enterprise Resource Planning II (ERPII) system to manage inventory and material flow through the company. Kanban boards are used to map the material flow through the production floor and to facilitate Just in Time (JIT) / Pull production system to reduce inventory & minimize waste.

Material management team supports project execution excellence by managing the quality and timely delivery of materials through our network of local and international network of vendors and suppliers. Material planning, procurement optimization, and vendor management strategies are used to ensure materials are delivered in line with the project schedules.

project management

_____

PM is responsible for the management of contractor/project schedules. They create internal design, supply chain, processing, production, manufacturing and installation schedules in coordination with Project Controls and Coordination department that in turn liases with design, materials management, operations, production and manufacturing.

All project schedules are created pre constrained to the project completion dates with early finish and late finish impacts built in. Sub schedules are integrated into the master program which in turn is what is used by the organization to ensure timely delivery of the project.

We use digitization to a large extent in our effort to reduce paper and print and make our processes environmentally friendly and more efficient enabling large teams to work across geographies seamlessly while ensuring quick turnaround. We use Oracle Primavera and Microsoft Project for Project management along with enterprise communication tools like Slack.

Before any work commences, our project management team breaks down the project in internal work packages from detailed design, procurement to installation, develop method statements, manpower and resource loading requirements. In doing so, resources are efficiently assigned and utilized to deliver the project successfully.

hse

_____

The health and safety of our employees are of paramount importance and Alutec is committed to developing and nurturing a safe work environment and “safety first”, culture within our organization. To this end, Alutec has developed a comprehensive HSE Program that complies with OHSAS 18001:2007 standards. All of our employees are required to go through an extensive HSE programme as part of their induction into the organization where we help them understand HSE regulations, requirements, training and guidance on their respective job functions. At the end of the HSE training they are provided with PPE, emergency call lists and counselor contacts. Additionally, continuous on the job training and periodic refresher courses are held with our staff that might include, Tool Box Talks (TBT) and updates on new regulatory frameworks or HSE management systems.

On jobsites, Job Safety Analysis (JSA) and Risk Assessments (RA) are conducted to identify potential worksite hazards and to determine whether sufficient precautions have been taken, to develop risk mitigation strategies and to implement the safest methods in executing the job.

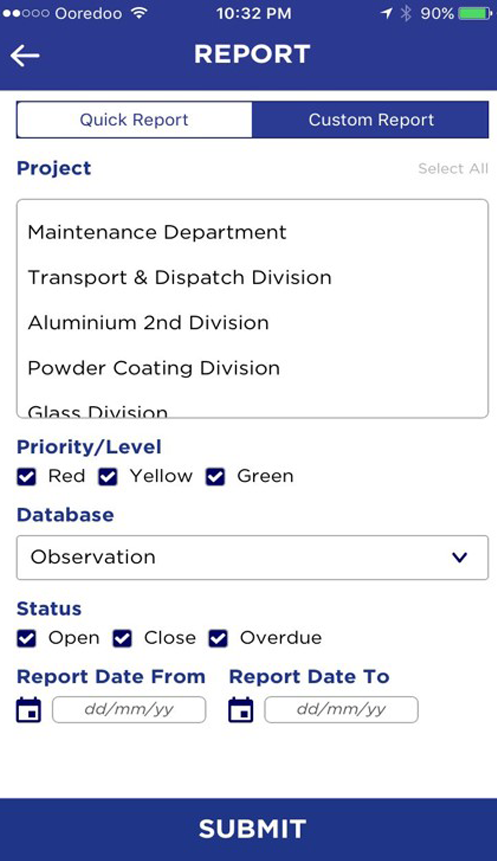

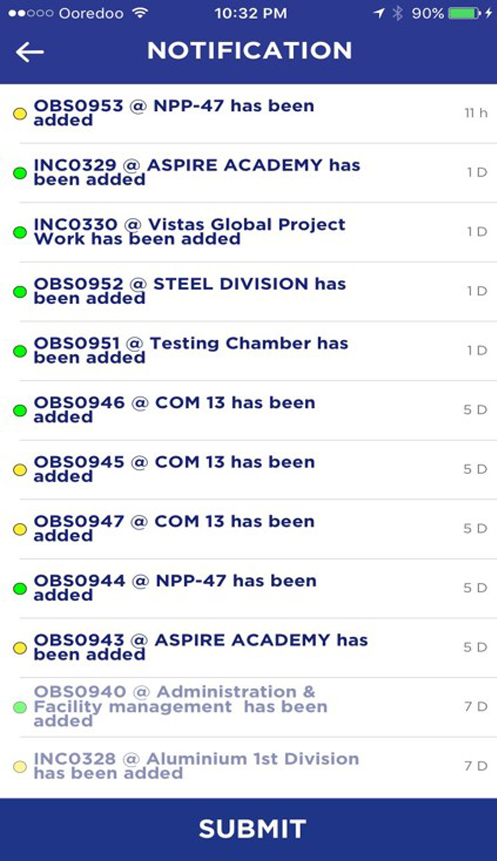

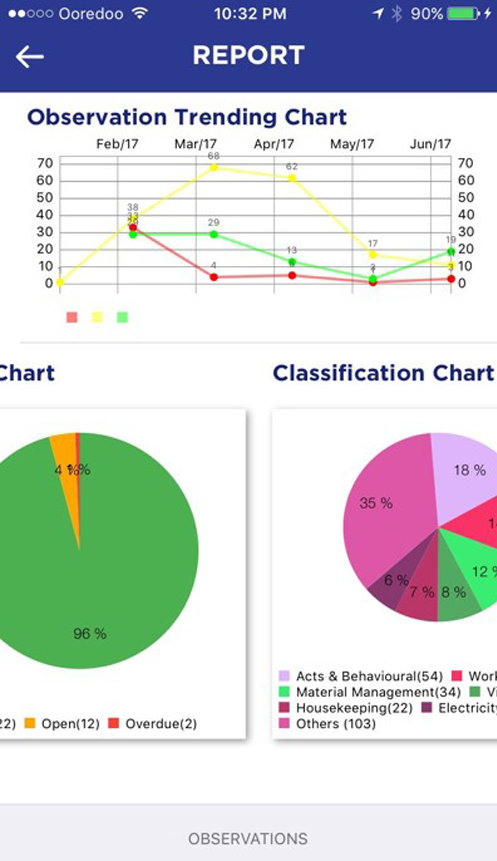

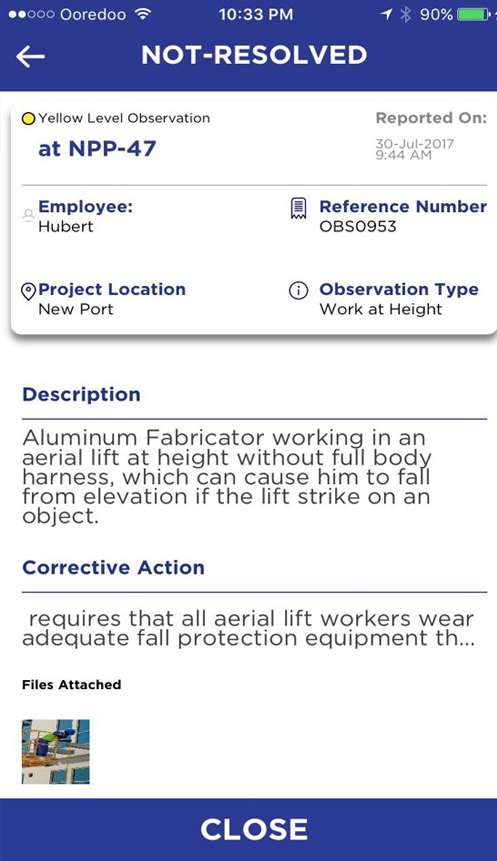

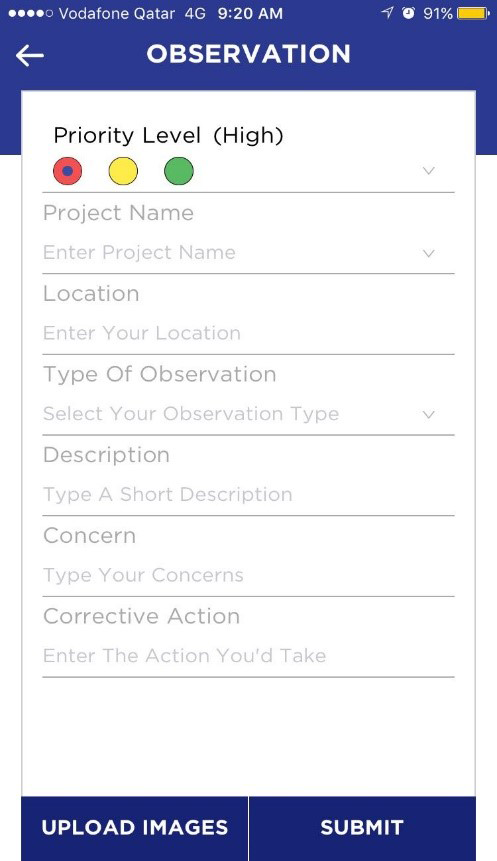

Monitoring and reporting are vital components of Alutec’s HSE program to ensure HSE program compliance. Through the aid of mobile HSE application tools, safety incidents and observations in factories and jobsites are reported, classified and documented. Safety alerts are published in real-time to all or concerned teams/ persons when there is a specific safety incident /observation so that the appropriate remedial actions are taken in a timely manner. HSE reports are generated at regular intervals for management and team review to proactively address safety issues and implement corrective actions and improvements to the HSE program.

Salus

The Salus App is designed such that any observation, incident or near-misses can be recorded and communicated along with pictures and prioritized using a traffic light system by the field personnel. The system uses a proprietary communication matrix algorithm that enables easy setup of company wide emergency protocols, which allows for the complex task of communication notifications, action management and generating reports to be simplified by the Salus system. Observation/Incident reports are notified to relevant personnel using a combination of App push notification and emails.

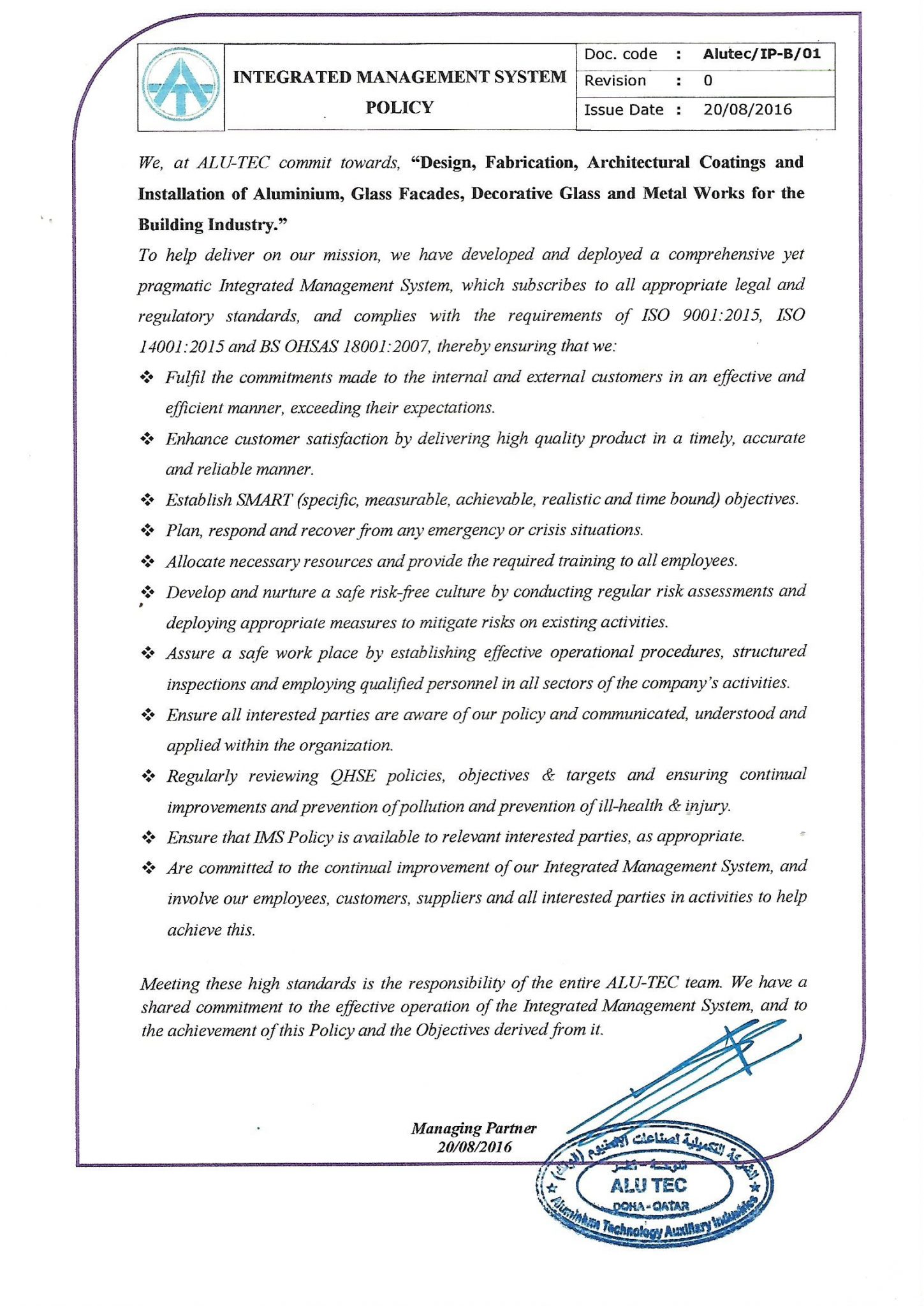

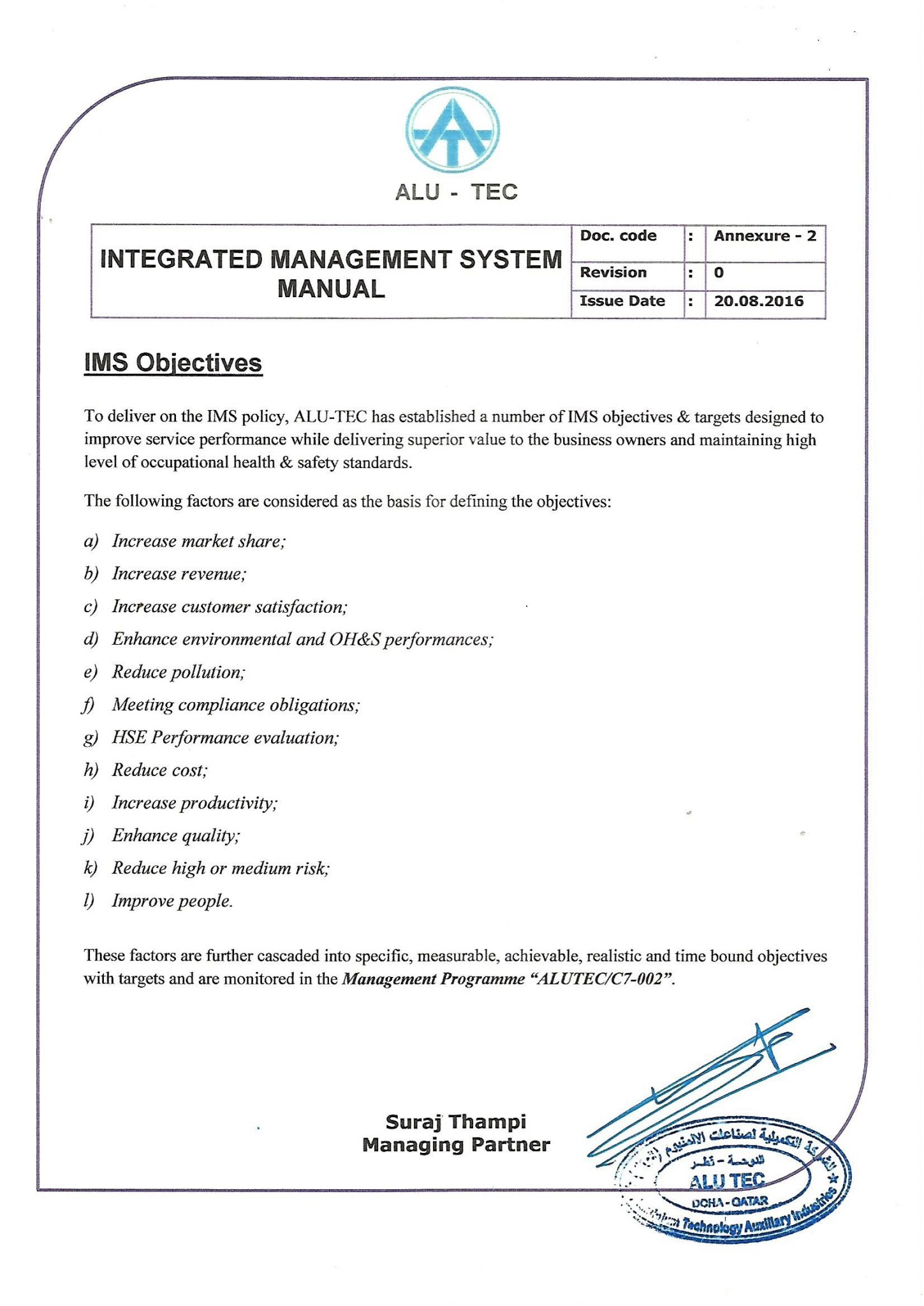

IMS Policy & Objectives

quality assurance & control

_____

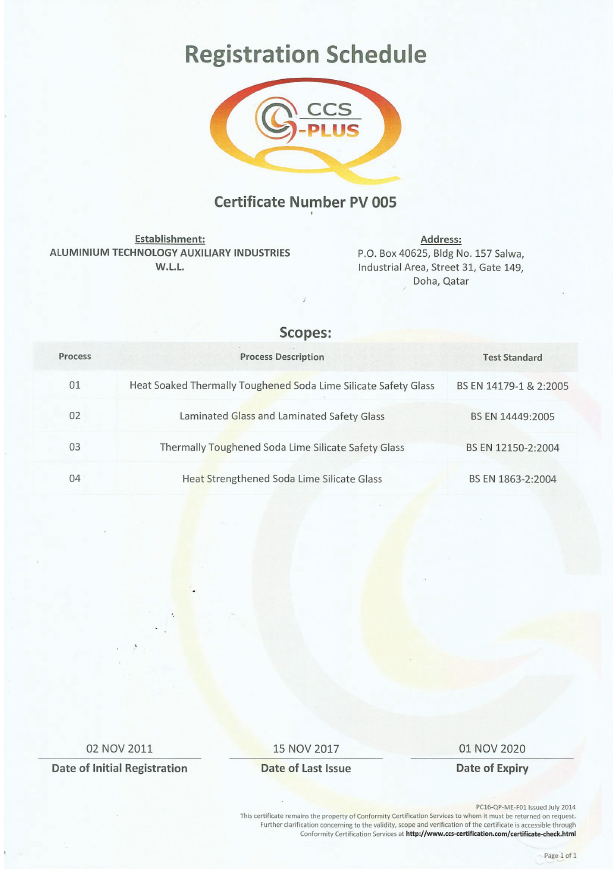

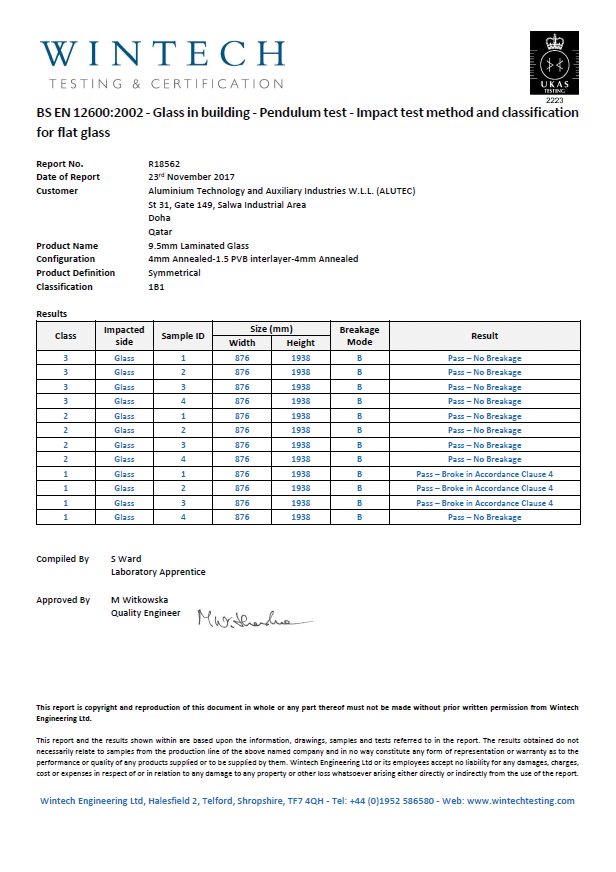

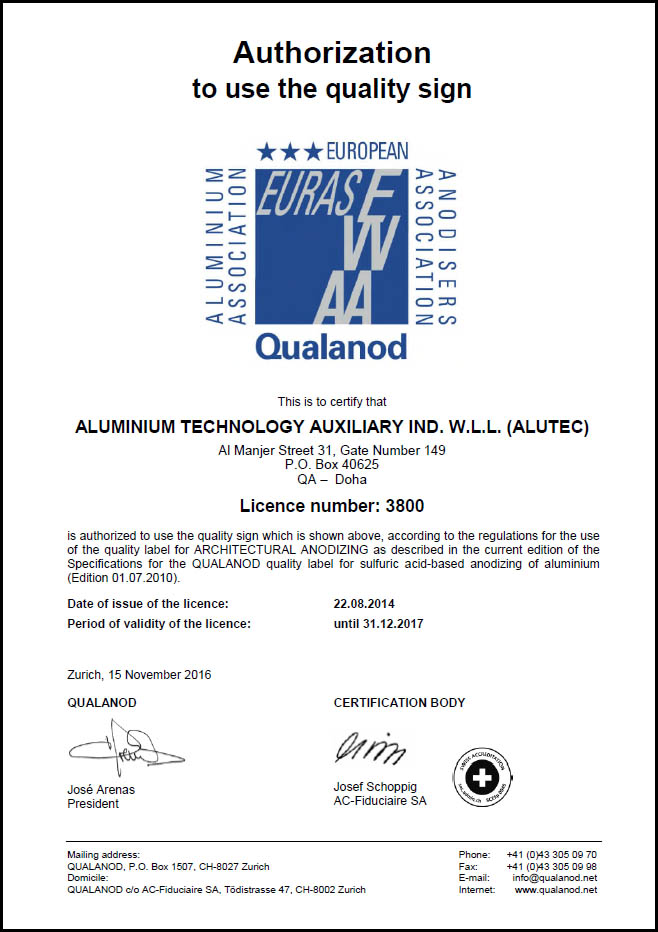

Alutec has a quality program governed and certified by IMS standards and are various industry standards like ISO 9001:2015 Quality Management System, ISO 14001:2015 Environmental Management System, BS OSHAS 18001:2007 Occupational Health & Safety Management System, IGCC, SGCC, Qualicoat and Qualanod.

Our Quality Assurance (QA) program streamlines production and ensures that the final products meet Alutec quality standards and comply with the project specifications. With the aid of tools like Job Orders and Job Cards, the quality and compliance of products are monitored at every workstation and throughout its lifecycle.

As a testament to our commitment to quality assurance, ALUTEC has established a life-size two storey high ‘testing chamber’ with comprehensive testing instruments within our facilities where performance mock-up tests are carried out and certified by independent third parties like CISRO.

Our Quality Control (QC) program ensures that inspections and audits are performed on incoming and outgoing materials in compliance with relevant international standards (ASTM, ANSI, AAMA, BSEN, GANA, AWS), project specifications, and Inspection Test Plan (ITP). Finished products that leave our facilities are QC checked, barcoded and scanned through our customized ERPII system to certify that they are compliant, free of defects and delivered as a complete kit.

Our QA/QC programs are continuously monitored and reported through our mobile application solutions where Quality records & observations are documented for compliance, benchmarked and continuously improved upon. The Management is committed to continuous improvement.

certifications

_____

contact us

_____

40625, Industrial Area, Doha, Qatar

Tel: +974 44602334

E-mail: info@alutecqatar.com